OUR PROCESSING

Hessian Beaming machine

Beaming process is follows after spool winding. In Beaming operation yarn from spool is wounded over a beam of proper width and correct number of ends to weave jute cloth. To increase the quality of woven cloth and weaving efficiency, the wrap yarns are coated with starch paste.

Adequate moisture is essential in this process. Quality characteristic of a beam is width of beam - number of ends and weight of stand and there is a continuous passage of yarn through starch solution from spools to the beam.

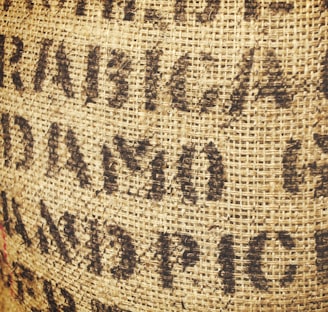

Weaving the Cloth

Weaving is a process of interlacement of two series of threads called "wrap" and "weft" yarns to produce the fabric of desired quality. There are separate looms for hessian and sacking in weaving section. The Hessian looms, shuttle which contents cops (weft yarn) is manually changed. The sacking looms are equipped with eco-loader to load a cop automatically into the shuttle.

Dumping

Dumping is the process in which the rolled woven cloth is unrolled and water is sprinkled on it continuously to provide desired moisture. Each roll is generally104 yards or 95.976 meters. Damping is done manually.

Calendaring

Calendaring is a process similar to ironing of fabric. After damping the damped fabric passes through pairs of heavy rollers rendering threads in fabric flattened and improve the quality and appearance.

Explore our services

A-twill bags

Explain what your service entails and why the visitor should use it

B-twill bags

Explain what your service entails and why the visitor should use it

Fashion bags

Explain what your service entails and why the visitor should use it

Contact us if you have any questions

Use this space to encourage visitors to get in touch with your team for questions, bookings, feedback, or just to say hi.